Table of Contents

- Hazard Class 1

- Hazard Class 2

- Hazard Class 3

- Hazard Class 4

- Hazard Class 5

- Hazard Class 6

- Hazard Class 7

- Hazard Class 8

- Hazard Class 9

Hazardous materials contain properties that could pose a risk to human health and safety, infrastructure and means of transport. They can be pure chemicals, mixtures of substances or products that are manufactured and could potentially harm people, animals or the environment if not properly handled when transported.

The United States Department of Transportation (DOT) provides a standardized system to categorize and identify various hazardous materials based on properties and risk levels. As a logistic manager, understanding these nine DOT hazard classes is important to properly handle dangerous goods and promote safety.

What Are the 9 Main Hazard Groups?

A hazard class is a collection of materials or substances that could potentially harm living organisms when transported. There are nine hazard classes in total, categorized based on specific properties and risk levels. Any mistake or oversight when it comes to DOT hazard class classification can lead to serious accidents, endanger lives or cause property damage. As a result, the DOT ensures strict regulatory requirements when shipping hazardous materials through ground, ocean or air.

A material’s hazard group is indicated by a number or name displayed in the lower corner of a placard. The hazard groups can be summarized as follows:

- Explosives: Materials that can detonate easily during a chemical reaction.

- Gases: Materials stored as compressed, liquefied or refrigerated gases that can be flammable, corrosive or toxic.

- Flammable liquids: Liquids with low flashpoints, or the minimum temperature that can cause vapor and easily ignite.

- Flammable solids: Solids that can be easily ignited and cause fires.

- Oxidizing substances: Materials that release oxygen, making them highly reactive to cause a fire.

- Toxic and infectious substances: Substances that can cause harm or death when exposed to living organisms.

- Radioactive materials: Radioactive materials that emit radiation and can be harmful to one’s health.

- Corrosive substances: Substances that erode or destroy other materials when they come into contact.

- Miscellaneous dangerous goods: Materials that don’t fit into the above classes but still pose harm.

These nine hazard groups are essential in logistics as they help managers properly identify and evaluate hazards, take steps to mitigate risks, safely store items, be prepared for emergency response, and promote worker safety and transportation compliance. Being able to properly classify and identify the materials can prevent civil and criminal penalties, safety incidents and revocation of hazardous shipping rights.

Hazard Class 1: Explosives

Explosives belong in hazard class 1 and consist of any reactive substance or article that contains a high amount of energy to produce an explosion if suddenly released. The explosion could be accompanied by light, heat, pressure or sound.

Class 1 explosives are represented by a placard with the designated hazard class, division number or compatibility letter noted at the bottom. Some also display an explosion graphic. Compatibility letters are marked A-S to indicate the products that are safe to travel with explosives.

Materials in class 1 can include:

- Cartridges

- Ammunition

- Flares

- Fuses

- Fireworks

- Pyrotechnics

- Blastic caps

- Detonators

- Primers

- Explosive charges

- Igniters

- Detonating cords

- Rockets

- Trinitrotoluene (TNT)

Based on test methods, materials in class 1 are divided into six subclasses of different explosives, with the lower division number indicating a higher potential for hazard. These substances can cause catastrophic damage to the surroundings. As a result, it’s crucial to be able to understand the explosive hazard classification and how to identify each type of substance.

Hazard Class 1.1

Subclass 1.1 consists of substances and articles that have a mass explosion hazard, or a mass explosion that impacts an entire load instantaneously. Even a small ignition source can cause these materials to react with a violent and immense force. Substances and articles within this subclass can include:

- Gunpowder

- Certain fireworks

- Rocket fuel

- TNT

Hazard Class 1.2

While many class 1 explosives are dangerous due to their explosive properties, subclass 1.2 explosives are specifically hazardous due to their capability of emitting dangerous projectiles at an explosive force. These materials can include:

- Certain types of ammunition

- Specific types of grenades

Hazard Class 1.3

Division 1.3 explosives carry the risk of a fire hazard in addition to having projection or explosive properties. These explosives are used for entertainment purposes and are provided in consumer or professional-grade displays. Common types of substances in this division include:

- Pyrotechnics

- Fireworks

These substances are in this category due to their flash power, which holds an explosive risk of creating a fire or minor blast but not a massive explosion.

Hazard Class 1.4

Division 1.4 substances cause minor explosions, mostly contained in their packaging. These materials only pose a slight risk of explosion if ignited or initiated during transport, yet their package will often confine hazards from the explosion, like large projectiles. Examples of class 1.4 explosives include:

- Tracers for ammunition

- Weapon cartridges

- Certain types of fireworks

- Distress signals

Hazard Class 1.5

Subclass 1.5 explosives carry the risk of mass explosion like explosives in subclass 1.1, but they are inert in most conditions. While they have the potential of creating a mass explosion, they are so insensitive that the likelihood is very small. They also carry a very small risk of transitioning from burning to detonation under normal conditions of transport. The minimum requirement of division 1.5 materials is they must not explode in the external fire test.

Hazard Class 1.6

Similar to division 1.5 explosives, 1.6 substances carry a minimal sensitivity to ignite and will not produce a mass explosion. These substances are highly insensitive and demonstrate a minor probability of initiation that is accidental.

Hazard Class 2: Gases

Class 2 Hazards are gases divided into three categories — flammable, non-flammable and non-toxic and toxic. Gases in these categories can be pure or a mixture of one or more gases, defined as having a vapor pressure greater than 300 kPa, or completely gaseous at a standard pressure of 101.3 kPa.

Examples of class 2 dangerous goods include:

- Aerosols

- Compressed gas

- Fire extinguishers

- Lighters

- Refrigerant gases

- Fire extinguishers

- Carbon dioxide

- Natural gases

These gases pose serious hazards due to their flammability, ability to oxidize, potential as asphyxiants, and toxicity or corrosiveness. Hazard class 2 subclasses are divided by their hazardous properties, including:

Hazard Class 2.1

Hazard class 2.1 consists of flammable gas, meaning it is ignitable when in a mixture of 13% or less by volume with air, or has a flammability range with air of at least 12% regardless of the lower limit. Examples include:

- Aerosols

- Some refrigerant gases

- Ethylene

- Propane

- Hydrocarbon gases

- Acetylene

- Hydrogen

- Lighters

- Methane

- Bytylene

Hazard Class 2.2

Division 2.2 consists of non-flammable and non-poisonous compressed gas. The material or mixture exerts in the packaging an absolute pressure of 280 kPa or greater at 20-degrees Celsius. These materials are used in various industries as well as households. Examples include:

- Aerosols

- Compressed gas

- Most refrigerant gas

- Fire extinguishers

- Nitrogen

- Carbon dioxide

- Nitrous oxide

- Helium

- Pressurized cryogenic gas

- Liquefied gas

- Asphyxiant gas

- Compressed gas in solution

- Oxidizing gas

- Rare gases and nitrogen mixtures

Hazard Class 2.3

Hazard class 2.3 includes poisonous gas or material that is a gas at 68 degrees Fahrenheit or below and 101.3 kPa of pressure. Division 2.3 materials are toxic to humans and pose a hazard during transportation. Examples include:

- Phosgene

- Chlorine

- Sulfur tetrafluoride

- Insecticide gases

- Ammonia

- Compressed coal gas

- Boron trichloride

- Boron trifluoride

- Cyanogen

- Hydrogen sulfide

- Silicon tetrafluoride

Hazard Class 3: Flammable Liquids

The hazard class for flammable liquid. A flammable liquid has a flashpoint at or above 100 degrees Fahrenheit, while combustible liquids are those with a flashpoint above 100 degrees and below 200 degrees Fahrenheit. Flammable liquids produce a flammable vapor which, when mixed with air, can ignite or explode, posing a danger. They can be extremely flammable, highly flammable or flammable, depending on their flashpoint and boiling point.

- Packing Group I: Materials presenting high danger

- Packing Group II: Materials presenting a medium danger

- Packing Group III: Materials presenting low danger

Combustible Liquids

Hazard class 3 consists of combustible liquid, too. Examples of combustible liquids include:

- Methyl alcohol

- Benzene

- Diesel fuel

- Kerosene

- Waxes and polishes

- Adhesives and cements

Flammable Liquids

Examples of flammable liquids in hazard class 3 include:

- Petroleum ether

- Acetone

- Acetaldehyde

- Ethyl chloride

- Paint and paint-related materials

- Cigarette lighters

Another common flammable liquid in hazard class 3 is gasoline, as well as items containing gasoline or gasoline fumes.

Hazard Class 4: Flammable Solids

Any solid that will rapidly undergo a combustion process due to an igniter is classified as a class 4 flammable solid. Class 4 substances begin to combust regardless of outside changes to pressure or density. They are susceptible to combustion without the help of chemical accelerants, making them potential threats to any industry that uses them.

Examples include:

- Firelighters

- Alkali metals

- Oily fabrics

- Aluminum phosphide

- Sodium batteries

- Metal powders

- Activated carbon

- Matches

- Camphor

- Sodium cells

- Carbon

- Calcium carbide

The U.S. Department of Transportation breaks this hazard class into three divisions:

Hazard Class 4.1

Division 4.1 consists of flammable solids, or solids that can easily combust and cause fire through friction. For example, hazard class 4.1 includes matches, as well as powdered, granular or pasty substances that can be easily ignited with brief contact with an ordinary source. In addition to the fire, flammable solids emit a toxic substance that can pose a threat to humans.

Examples include:

- Matches

- Nitrocellulose

- Magnesium

- Sulfur

- Phosphorous

These items can spontaneously ignite or combust from friction or static electricity. Even in normal temperatures or pressures, they can cause fires, burning rapidly and creating intense heat that can be ignited even by a small source.

Hazard Class 4.2

Division 4.2 includes spontaneously combustible solids. These are materials that can spontaneously generate heat during transport, leading to a fire. Examples include:

- Self-heating substances: A solid or liquid that can ignite with air when exposed for five minutes.

- Pyrophoric substances: A self-heating material that is susceptible to self-heating. These substances will only ignite in large amounts and after a long period of time.

Hazard Class 4.3

Hazard class 4.3 includes dangerous when wet substances. Also known as reactive solids, these materials react when water touches them, emitting a flammable gas that can form explosive mixtures with air. These solids can be easily ignited by all ordinary sources that produce a spark.

Examples include:

- Calcium

- Aluminum phosphide

- Sodium

- Calcium carbide

- Potassium

- Zinc particles

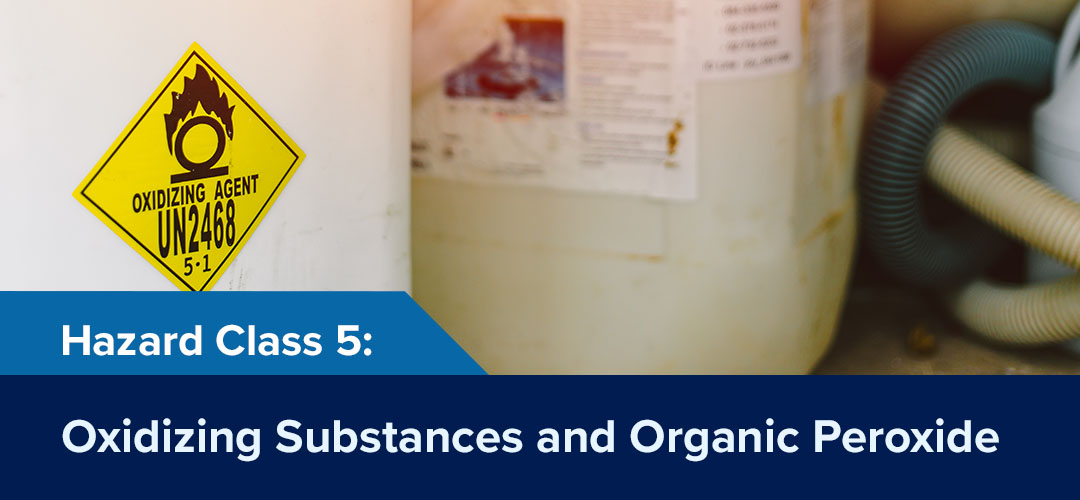

Hazard Class 5: Oxidizing Substances and Organic Peroxides

Dangerous goods class 5 includes materials that can ignite or oxidize depending on their subclass. These are flammable substances in liquid or solid form that pose a physical-chemical hazard.

Common examples include:

- Pressurized gas packages

- Fertilizers containing ammonium nitrate

- Organic peroxides with more than 7% hydrogen peroxide

The greatest danger of hazard class 5 substances comes from their ability to supply oxygen for combustion. Especially at higher temperatures and in combination with other substances, this can lead to detonation. If any of these materials come into contact with flammable substances, they can cause a fire or explosion and run the risk of producing toxic gases.

Additionally, class 5 dangerous goods are self-decomposing when combined with heat and light, triggering a chemical reaction when combined with acids and water. Hazard class 5 substances are divided into flammable or oxidizing substances hazard class 5.1, and organic peroxides class 5.2.

Hazard Class 5.1

Class 5.1 substances are those that are not necessarily combustible but can yield oxygen and cause or contribute to the combustion of other materials. Oxidizing substances can be solid or liquid. Examples include:

- Nitrates

- Calcium hypochlorite

- Ammonium nitrate

- Nitrites

- Chlorates

- Peroxides

- Hydrogen peroxide

- Calcium nitrate

- Calcium peroxides

- Oxygen

- Potassium chlorate

Hazard Class 5.2

Materials in hazard class 5.2 are divided into organic peroxides that either require or do not require temperature control to decompose. Organic peroxides are thermally unstable and have the capability of exuding heat when undergoing exothermic autocatalytic decomposition. In contrast to class 5.1, their composition can result in the risk of explosive reactions or a stronger fire when reacting to other flammable substances.

Examples include:

- Dibenzoyl peroxide

- Methyl ethyl ketone peroxide

The above substances can be susceptible to explosive decomposition, react dangerously with other substances, burn rapidly, be prone to impact or friction, and cause damage to the eyes.

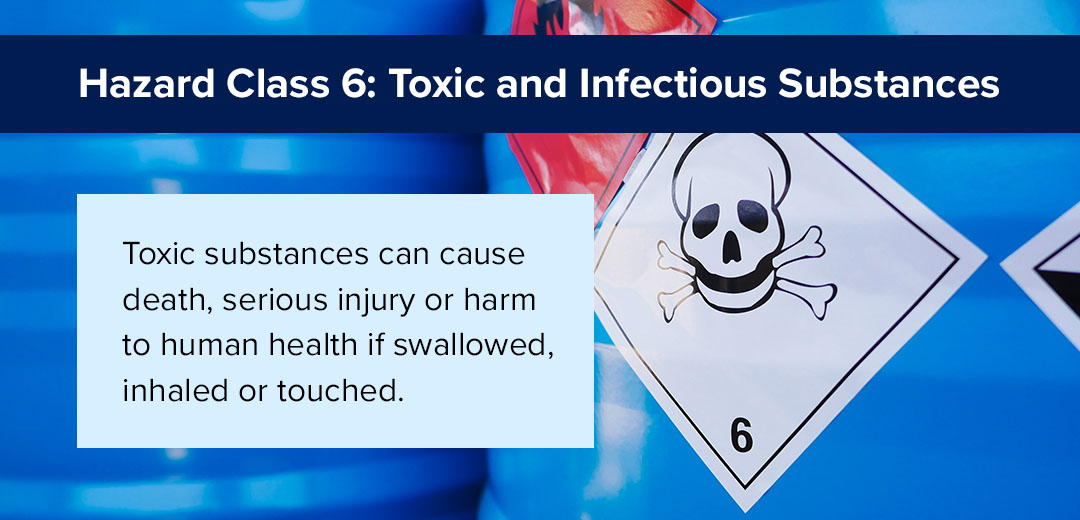

Hazard Class 6: Toxic and Infectious Substances

Class 6 hazardous materials include toxic and infectious substances. Toxic substances can cause death, serious injury or harm to human health if swallowed, inhaled or touched. Infectious substances are reasonably expected to contain pathogens, defined as microorganisms like viruses, bacteria, parasites and fungi, or agents that can cause disease in humans or animals.

Common transported toxic and infectious substances include:

- Medical and biomedical waste

- Clinical waste

- Motor fuel anti-knock mixture

- Tear gas substances

- Dyes

- Arsenic compounds

- Carbamate pesticides

- Alkaloids

- Acids

- Cyanides

- Mercury compounds

- Arsenates

- Nicotine and nicotine compounds

- Biological or medical cultures, samples and specimens

Hazard class 6 divisions include:

Hazard Class 6.1

Division 6.1 includes substances that, in small quantities and by a quick single action, can cause damage to human health by inhalation, absorption or ingestion. Hazard class 6.1 includes substances in either solid or liquid form. They are presumed toxic because they fall within any one of the following categories when tested:

- A liquid or solid substance with a lethal dose 50 (LD50) for acute oral toxicity under or equal to 300 mg.

- A substance with an LD50 for acute dermal toxicity under or equal to 1000 mg.

- A mist or dust with a lethal concentration 50 (LC50) for acute toxicity on inhalation under or equal to 4 mg.

Examples of hazard class 6.1 substances include:

- Arsenic

- Cyanide

- Nicotine

- Chloroform

- Lead

- Mercury substances

- Pesticides

Hazard Class 6.2

Class 6.2 dangerous goods include materials known to reasonably expect to contain pathogens like bacteria, parasites, viruses, fungi and other agents. Infectious substances can be:

- Biological products

- Patient specimens

- Medical and clinical waste

- Cultures

If transported in a form that can lead to exposure, these substances can cause life-threatening or fatal diseases and permanent disability to otherwise healthy humans or animals. For instance, they might cause ebola virus, hepatitis B virus, rabies virus, yellow fever virus in humans or African swine fever virus in animals.

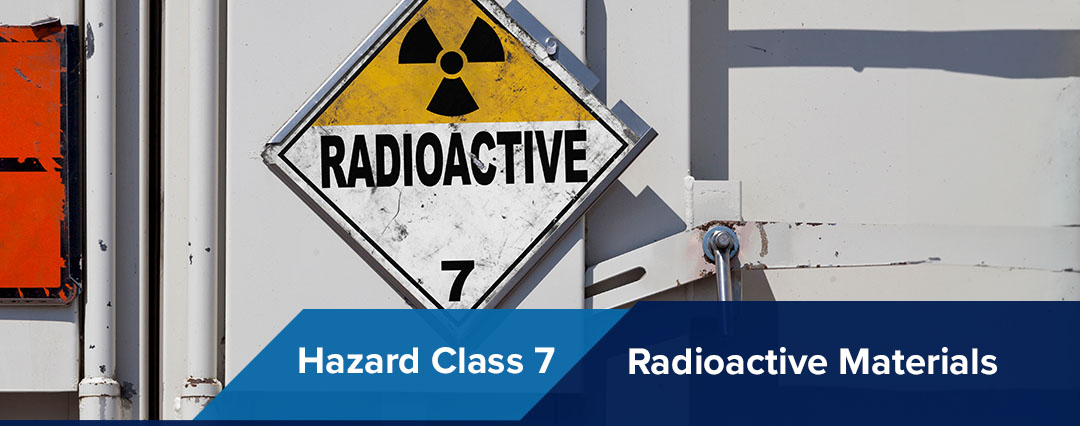

Hazard Class 7: Radioactive Materials

Hazard class 7 radioactive materials are any substance containing radionuclides where its activity concentration and total activity exceed specific predefined values. A radionuclide is an atom with an unstable nucleus that is susceptible to decay. The radionuclide will emit ionizing radiation, which can present severe risks to human health. Since radioactivity can’t be tasted or smelled, these substances can particularly pose a danger.

Common examples of class 7 dangerous goods include uranium and plutonium, which occur in instruments and objects, such as X-ray equipment and technical testing equipment used in quality control. Other examples include:

- Fire suppression systems

- Density gauges

- Smoke detectors

- Depleted uranium products

- X-ray machinery

- Medical isotopes

- Radium isotopes

- Yellowcake

- Mixed fission products

- Plutonium isotopes

- Surface contaminated objects

While there are no divisions or subclasses within class 7, transport labels and cargo transport placards can vary depending on the content and activity of the radioactive material. You can determine the proper label based on the calculated transport index and radiation level measured at the surface of the package, with RADIOACTIVE WHITE-I at the lowest category and RADIOACTIVE YELLOW-III at the highest:

- Category I White (7A): This subclass includes radioactive substances with the highest surface dose rate below 0.005 mSv/h.

- Category II Yellow (7B): This includes category II radioactive substances that can lead to external radiation exposure, with a surface dose rate between 0.005 mSv/h and 0.5 mSv/h.

- Category III Yellow (7C): This subclass includes radioactive substances with radiation doses between 0.5 mSv/h and 2 mSv/h.

- Category III Yellow (7D): Combined with 7C, this subclass includes radioactive substances with a dose rate at the outside that can be greater than 2 mSv/h, but may not exceed a value of 10 mSv/h.

For example, a package with a transport index of 0.8 and a maximum surface radiation level of 0.6 mSv/h must be affixed with a RADIOACTIVE YELLOW-III label.

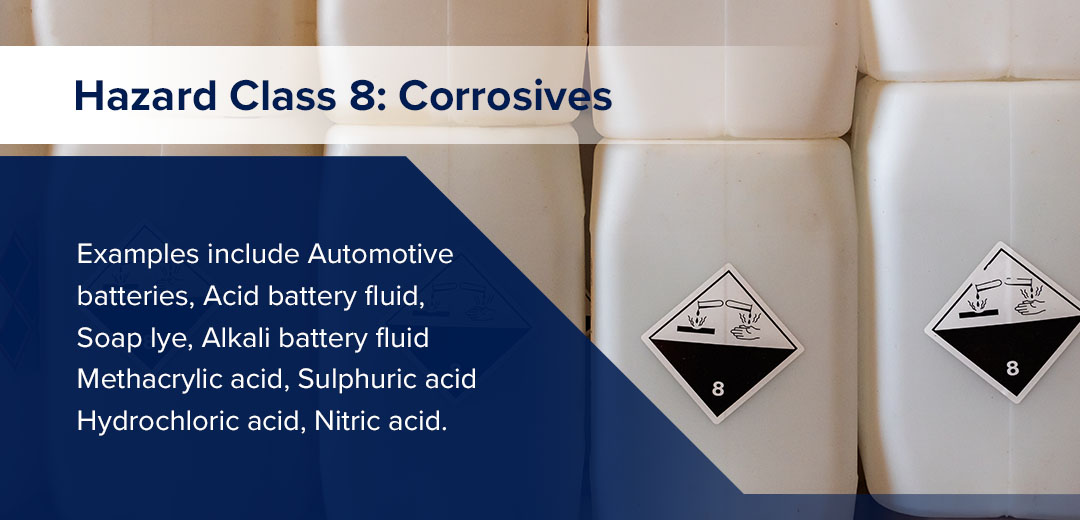

Hazard Class 8: Corrosives

Hazard class 8 consists of corrosive substances. These materials, by chemical action, can attack surfaces and destroy living tissue, causing irreversible damage to the skin or other goods in the event of leakage during transport. As a result, handling must be carried out properly to prevent risks. Corrosive substances can be in either solid, liquid or gas form, and they are classified according to their properties — corrosive acids or alkalis that are either organic or inorganic.

Automotive batteries are an example of hazard class 8, due to the corrosive sulfuric acid inside a typical car battery. Other substances in the corrosive hazard class include:

- Acid battery fluid

- Soap lye

- Alkali battery fluid

- Methacrylic acid

- Sulfuric acid

- Hydrochloric acid

- Nitric acid

Class 8 hazardous materials do not have divisions but can be grouped into acids or alkalis. While neutral substances have a pH equal to 7, acids have a pH of less than 7, and alkalis have a pH greater than 7. Alkalis include sodium hydroxide, potassium hydroxide and ammonia. Acids include nitric acid, hydrochloric acid and phosphorous acid.

Hazard Class 9: Miscellaneous Dangerous Substances and Articles

Hazard class 9 includes dangerous substances and articles that present a hazard during transport, but do not meet the definitions of the other hazard classes. While Class 1 through Class 8 specifically defines the hazards they present in the way of combustion, corrosion, toxins, lethality and radioactivity, class 9 is purposefully left vague.

Still, the DOT requires any type of transportation of any hazardous material or waste to be labeled, packaged, handled and stored properly to reduce any risks to humans and the environment. These include any material with noxious, anesthetic or similar properties that could cause annoyance or discomfort to a flight crew member, driver or boat pilot, preventing them from doing their jobs properly.

Common examples of hazard class 9 substances include:

- Live-saving appliances

- Substances involving flammable vapor

- Dry ice

- Automobile airbags

- First aid kits

- Asbestos

- Self-defense sprays

- Environmentally hazardous substances

- Battery-powered vehicles

- Dangerous goods in machinery

- Dust-like substances that can endanger health when inhaled

- Substances and articles that can form dioxins in the event of a fire

- Battery-powered equipment

- Chemical kits

- Substances transported at an elevated temperature

- Genetically modified microorganisms and organisms

The second part of the definition of class 9 materials is hazardous substances or wastes, marine pollutants, and any elevated temperature materials subject to DOT requirements. Elevated temperature substances include:

- Liquids at a temperature at or above 212 degrees Fahrenheit.

- A liquid phase material with a flashpoint at or above 100 degrees Fahrenheit that is intentionally heated.

- A solid phase material at a temperature at or above 464 degrees Fahrenheit.

Hazard Class 9a: Lithium Batteries

Lithium batteries belong to hazard class 9a. These cells and batteries power numerous items used every day, from portable computers and mobile phones to watches, wheelchairs and motor vehicles. Today’s lithium cells and batteries are even more energy-dense, bringing increasingly higher-powered devices to market. With greater energy density comes greater risk and requirements to manage it. As a result, lithium batteries fall under the DOT hazard classes, with each mode of transport carrying its own risk.

When transporting lithium batteries, logistics workers must follow the appropriate legislation depending on land, sea, inland, waterway or air mode of transport:

- The European Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR)

- The International Carriage of Dangerous Goods by Rail (RID)

- The International Civil Aviation Organization (ICAO) Technical Instructions (TI) for the Safe Transport of Dangerous Goods by Air and the International Air Transport Association (IATA) Dangerous Goods Regulations

- The International Maritime Dangerous Goods Code (IMDG Code)

While infrequent, lithium cells and batteries can also experience thermal runaway, a chain reaction causing a violent release of stored energy and flammable gas. This reaction can be distributed to other batteries or conducive substances nearby, potentially leading to large-scale thermal events with extreme consequences. As a result, it’s crucial that logistic managers can identify lithium cells and batteries and know how to properly sort, store and ship them to mitigate risks.

How Do You Identify Hazard Classes?

Being able to identify and understand the hazard classes is crucial in safely handling and transporting hazardous goods. As a logistics manager, you can identify hazard classes by considering the following factors:

- Material properties: Start by assessing the properties and characteristics of the material, including whether it is a solid, liquid or gas, and its potential hazards, including flammability, reactivity, toxicity or corrosiveness. You can use the material safety data sheets (MSDS) or safety data sheets (SDS) to learn more about dangerous goods’ properties and risks.

- DOT regulations: Follow the Department of Transportation Hazard Classes regulations for U.S. shipments and the International Maritime Organization (IMO) regulations for international shipments. Following the specific criteria and instructions, you can classify the hazardous materials you’re working with into the correct hazard classes. The DOT Hazardous Materials Regulations (HRM) or the Emergency Response Guidebook (ERG) are highly useful in understanding the classes and their criteria, including thresholds, properties and test methods.

- Labels and markings: When sorting materials, check for labels or markings on the packaging. You can identify specific hazards from their standardized symbols or pictograms. Labels are color-coded and include a visual reference to identify the specific hazard associated with the substance.

- Material testing and documentation: In some cases, you might not be able to determine the hazard class of a material accurately without a laboratory test. Specific tests can determine properties like pH level, corrosiveness, flashpoint or explosiveness of a material to help you classify it properly. Additionally, suppliers and manufacturers might also include documentation to help you identify the hazard class.

- Expert consultation: When in doubt or dealing with hazardous materials, consult with experts. At EMO Trans, we customize our logistics services to fit each client’s needs and requirements. We have in-depth knowledge and experience with DOT hazard classes and can guide you on accurate identification, ensuring the safer handling and transport of hazardous materials.

Importance of Understanding Hazard Classes

Understanding the dangerous goods hazard classes is crucial in the logistics industry for the following reasons:

Safety

Understanding hazardous materials and their properties can help you implement measures to minimize accidents, injuries or environmental impact when handling, storing and transporting these materials. For example, you’ll be able to implement risk management strategies like specialized equipment, safety protocols and contingent plans to properly handle emergencies.

Regulatory Compliance

Knowledge of hazard classes is crucial for compliance purposes. National and international authorities have established guidelines and requirements logistic operators must adhere to when dealing with hazardous materials. Failing to comply can result in fines, legal problems and disruptions to your operations.

Proper Handling and Storage

Understanding the number of hazard classes and their properties can help you identify features like flammability, corrosiveness, reactivity and toxicity. This knowledge allows you to correctly handle, package, label and store hazardous materials to minimize accidents, spills or contamination.

Effective Communication

Understanding each hazard class can ensure clear and consistent communication among logistics professionals, regulatory authorities and emergency responders. The DOT regulations provide a common language to be shared regarding the properties of hazardous substances, risks and necessary precautions — enhancing collaboration and ensuring safe operations.

Contact EMO Trans, Inc. for Your Logistics Needs

Understanding hazard classes and how to identify hazardous materials is vital in the logistics industry. It ensures the safety of personnel, protects the environment, helps you comply with regulations, and ensures proper handling, storage and transportation of dangerous goods.

No matter the complexity of your cargo challenges, we’ve got you covered. Our logistics services can include hazardous goods classification to promote efficient transportation and safer processes for your operation. We can help oversee the planning, execution and management of transport, ensuring products reach their destinations safely and on time.

To learn more about how we can help your company succeed, request a quote today.