People in the transportation industry often hear buzzwords like supply chain and logistics management. While these terms may seem to reference similar elements of the good transportation processes, there are significant differences between them and the roles respective managers tackle.

Below, you can learn more about these differences and how to optimize your processes.

Understanding the Difference Between Logistics and the Supply Chain

Supply chain management refers to the processes involved in using raw materials to create finished goods and transport them to the customer. Logistics services refer to the planning and execution of storing and moving goods to various points in the supply chain.

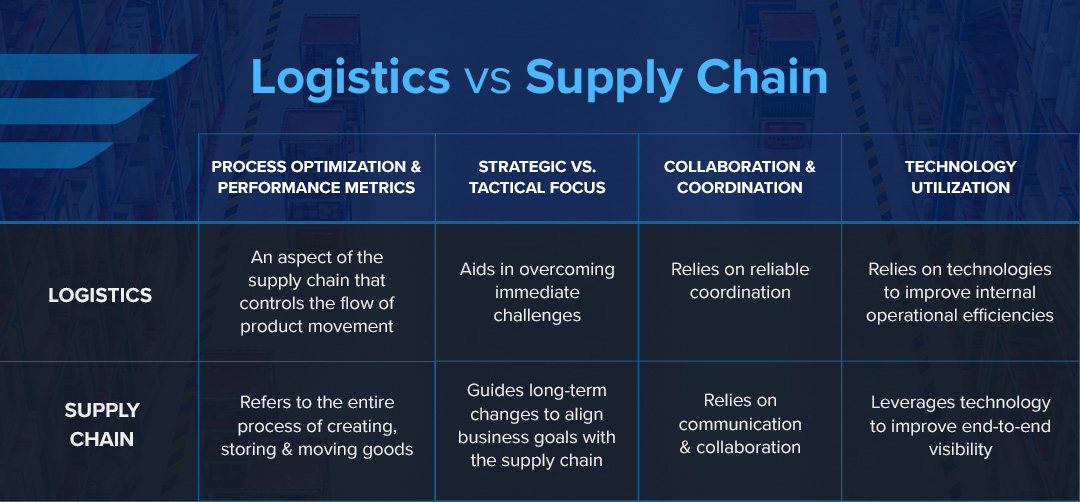

Although there are several similarities between logistics and supply chain management, there are also significant differences, including the following.

1. Process Optimization and Performance Metrics

Supply chain management refers to the entire process of creating, storing and moving goods. Its goals are to optimize and improve resilience from start to finish.

Logistics is an aspect of the supply chain that controls the flow of product movement — it aims to deliver the correct products to the correct destination promptly.

Teams often measure logistics performance by evaluating information related to order accuracy, transportation costs, delivery times and inventory turnover. These metrics help identify existing obstacles and inefficiencies for future optimization.

Supply chain management relies on a much larger scope of performance metrics. Elements like customer satisfaction levels, supply chain costs, market change flexibility and lead times can depict team efficiencies and opportunities for optimization.

2. Strategic vs. Tactical Focus

Another difference between these two terms is their strategic or tactical focus. Simply put, logistics aids in overcoming immediate challenges, while supply chain management guides long-term changes to align business goals with the supply chain.

Logistics has a more tactical focus, aiming to optimize day-to-day decisions and operations. Process improvement solutions may include tasks like managing transportation schedules, maintaining inventory levels and optimizing warehousing space.

Alternatively, supply chain management operates with a more strategic focus. Supply chain management emphasizes long-term goals and aims to guide decisions that impact the entire supply chain. To complete this objective, people in supply chain management roles often need to analyze market trends, maintain supplier relationships and leverage demand forecasting.

3. Collaboration and Coordination

Logistics often relies on reliable coordination. Coordinating functions such as warehousing activities and transportation routes helps teams achieve operational efficiency. Logistics information typically transfers between internal stakeholders and local teams directly interacting with logistics departments.

Alternatively, the supply chain relies on communication and collaboration. Supply chain managers must maintain relationships with retailers, distributors, suppliers, manufacturers and all stakeholders. This intense collaboration is crucial for ensuring a harmonious flow throughout the entire supply chain. Effective supply chain management focuses on forging and strengthening partnerships and finding ways to efficiently communicate with the entire network.

The differences in collaboration result in varying information flows as well. For example, Logistics relies on real-time information to understand product movement and operational performance. Internal teams can share this data to make process decisions. However, supply chain management has a broader flow of information and requires historical, current and future prediction information. Supply chain management teams must share relevant information across the network to drive operational changes.

4. Technology Utilization

With different goals and processes in mind, logistics and supply chain management leverage unique tools for optimization. Logistics operations typically rely on technologies to improve internal operational efficiencies. Tools like transport management systems, warehouse management systems and real-time tracking allow logistics teams to understand how products move and uncover ways to enhance movement efficiencies.

On the other hand, supply chain management leverages technology to improve end-to-end visibility. These tools aid in enhancing communication and uncovering trends to better understand the entire supply chain. Advanced technologies like Artificial Intelligence and machine learning empower teams to access highly accurate information regarding demand forecasting, historical trends and market data to drive real-time decision-making.

What Is the Difference Between a Logistics Manager and a Supply Chain Manager?

Given the differences between supply chain management and logistics, it’s no surprise that there are some distinctions in the management roles. A logistics manager may engage in activities like:

- Managing transportation: Efficient transportation is crucial for the logistics team’s success. After procurement, goods must move to distribution centers or production facilities. Depending on product volume, final destination and movement urgency, products may need various forms of transportation to arrive on time. Managers may need to coordinate plane, ship, train or truck routes.

- Optimizing inventory and warehousing: Some logistics teams heavily emphasize storing and warehousing activities. Optimizing these spaces, creating efficient processes for product retrieval and using real-time tracking information empowers product movement and cuts associated costs.

- Completing order fulfillment processes: Logistics team members may engage in activities related to proper packing and labeling for order fulfillment. Some processes require stringent standards or regulation compliance, such as processes involving hazardous materials or teams needing to meet size and weight restrictions.

- Monitoring distribution: Logistics teams also monitor distribution. This process may involve providing tracking information to the end user, sending updates to the customer regarding product movement and ensuring the goods arrive at the correct location.

Supply chain managers may engage in activities like:

- Sourcing raw materials: At the start of the supply chain, managers may engage in sourcing activities to meet compliances, ensure quality assurance, find cost-effective product solutions and gain competitive advantages.

- Analyzing demand predictions: Supply chain managers must analyze market trends, historical data and customer behavior to understand and predict future product demand. Accurate forecasting aids in ensuring adequate inventory levels, resource allocation and production schedules.

- Engaging in customer service: Customer feedback often guides process optimization. Supply chain managers engage in customer service activities such as managing reverse logistics, providing tracking information, ensuring order fulfillment and collecting and analyzing feedback for continuous improvement.

- Overseeing the production process: Supply chain managers often interact with the production process in various ways. These managers may coordinate between departments, aid in production planning or scheduling, direct supplier coordination or help with process improvement.

Optimize Your Product Movement Processes With EMO Trans

EMO Trans is your single-source global logistics solution provider and a reliable supply chain partner. We can help you improve operational efficiencies by streamlining routine tasks and simplifying core functions. Whether you need supply chain management assistance or want to optimize logistics, we can help.

Our comprehensive supply chain solutions empower you to manage an international supply chain with efficiency and affordability. Our global logistics solutions empower teams to navigate complex international logistics with a functional and efficient system.

Request a quote to learn more about our unique capabilities and how we can enhance your operations.