A tracking system is essential for storing, packing and shipping merchandise and protecting yourself from loss. While some companies still use bar codes to track their merchandise, others are switching to radio frequency identification (RFID) systems because they offer many benefits compared to bar codes.

RFID systems use wireless tags that transmit radio signals to reader equipment. They save a lot of time because they don’t require visual or physical contact to be read. When you use an RFID system, you can reduce warehouse errors and inventory cost management.

In this article, we’ll cover the benefits of RFID warehouse management systems and how these systems work. We’ll also discuss how you can start using RFID tags to simplify management at your warehouse.

What Benefits Does RFID Provide to Your Business?

RFID warehouse management systems (WMS) can help address inefficiencies in warehouses across many industries. For example, many warehouses experience trouble with:

- Shipping bottlenecks

- Difficulty tracking items

- Inaccurate inventory

- Slow data entry

- Poor data analytics

Using an RFID system in your warehouse can give you the data and quick access you need to improve warehouse processes and save time and money. They also significantly improve tracking details, allowing you to follow products throughout their transportation in real time.

Benefits of RFID Systems

Here are some of the most beneficial RFID use cases in an RFID warehouse system:

- Real-time tracking: With an RFID system, your products are automatically registered at each stage of the supply chain. This means you can check on items at any time and know exactly where they are instead of just where they were recently.

- Supply-chain visibility: The visibility of real-time tracking can help you identify bottlenecks in your supply chain. With this additional data, you can improve supply chain logistics for faster transport with fewer hiccups.

- Faster processing: When you use an RFID system, reader equipment can log multiple tags at the same time. This can significantly reduce how long it takes to enter product data, making inventory and checkouts much faster.

- Labor savings: The speed and simplicity of an RFID system ultimately add up to reduced labor costs. You won’t need to pay employees for as long to complete the same amount of work.

- Reduced human error: Automatic tracking systems like RFID minimize human error in inventory, organization and tracking. Instead of having to physically scan a bar code, the system will automatically log a product’s presence.

- Heightened security: The real-time tracking capabilities of RFID tags make them perfect for high-value items. By tagging expensive products, you can help reduce theft and company loss.

- Improved data analytics: Because RFID has higher accuracy, it also gives you improved data about tracking, inventory and your supply chain. You can leverage this data to improve processes and revenue.

The benefits of using an RFID stock management system are extensive — almost every area of management can experience improvements through RFID because of its faster speed and higher accuracy. Ultimately, switching to an RFID system can save you a great deal of time and money.

How RFID Systems Work

RFID technology uses antennae, radio signals and reader equipment to track products. Here’s how it works:

Each product is tagged. RFID tags include information like a product’s ID and location. Tags also include antennas that send radio signals to reader equipment. There are multiple options for where to place tags, depending on the size and shape of products.

When tagged products arrive at a location with an RFID reader, the reader sends out radio waves that activate the tags that are within range. Once activated, tags send their information to the reader. Proximity between a reader and functioning tags is the only thing necessary for clear communication — you don’t need a clear line of sight.

Readers forward received data to a tracking database, saving you the time it takes to manually input information or physically scan bar codes. They can receive data from multiple items at the same time.

Once data has been automatically recorded by RFID readers, it’s accessible for you to review within the database software. You can look at information like where products are in the supply chain or where they’re stored in your warehouse. You’ll also know when they arrive at each location.

3 Types of RFID Tags

There are several different types of RFID tags, and the best choice for your products depends on factors like affordability, read ranges and environmental factors like temperature or metal proximity. Here are three different types of RFID tags with different power source options:

- Passive: This type of RFID tag is powered by a reader’s electromagnetic field. They need to be fairly close to readers for their information to be picked up. Passive tags are more affordable than other options and are often used for inventory management and tracking.

- Active: Active RFID tags have their own internal battery. They can send out radio signals without waiting to be activated by a reader. Their read ranges are longer, meaning you can receive their radio signals from farther away. However, they cost more than passive tags. Active tags are often used to track large or high-value products.

- Semi-passive: Also known as battery-assisted RFID tags, semi-passive tags have an internal battery but rely on a reader’s signal to send data. They’re priced moderately, between passive and active tags. This kind of tag is a good fit for harsh environments or temperature changes.

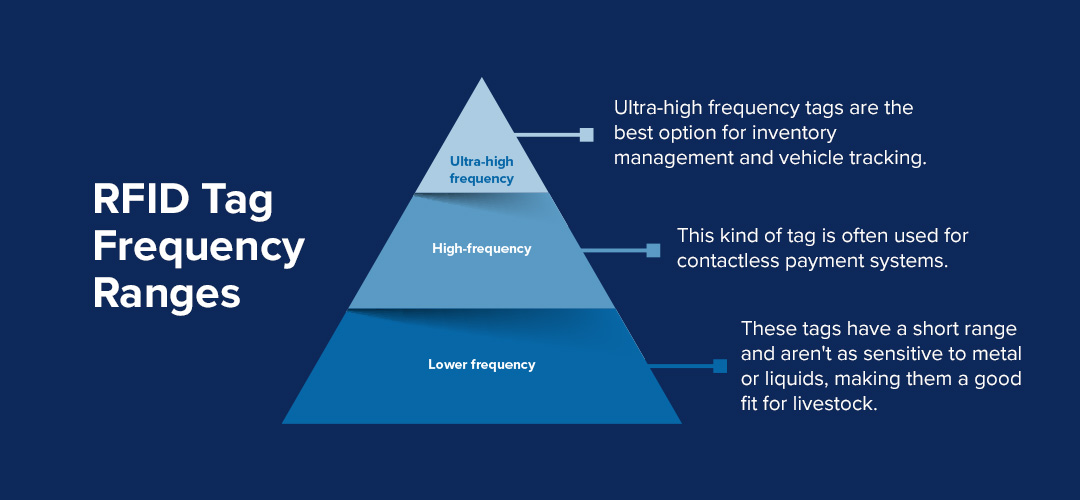

RFID Tag Frequency Ranges

One of the limitations of RFID tags is that they have to be within range of a reader to be accurately logged and tracked. You can purchase RFID tags that have different frequency ranges:

- Lower frequency: These tags have a short range and aren’t as sensitive to metal or liquids, making them a good fit for livestock.

- High-frequency: By contrast, this kind of tag has a longer range and supports high data transfer rates. This kind of tag is often used for contactless payment systems.

- Ultra-high frequency: These tags have the longest read range and readers can read multiple of these tags at once. Ultra-high frequency tags are the best option for inventory management and vehicle tracking.

RFID vs. Barcodes

If you’re already using a barcode system, you might wonder whether it’s worth it to switch to an RFID system. Barcode and RFID systems have several things in common:

- Unique markers like barcodes or tags

- Scanning equipment like barcode scanners or RFID readers

- An online database that stores data entries

At the most basic level, both systems work the same way. Each individual product is marked with a unique identifier. Any time an item is moved, it’s scanned and its information is stored and updated in a database. So far, these systems look very similar.

However, RFID stands out because of its higher speed and accuracy. Barcodes require line-of-sight to be scanned and they must each be scanned one at a time. They also must be close to the scanner for their data to be registered and transferred to the database.

By contrast, RFID tags can be scanned from a distance. Because RFID systems use radio signals instead of requiring a visual scan, RFID readers can save time by recording multiple RFID tags at once. Tags are scanned automatically once they’re within range, and their information is then automatically sent to the database.

How Much Do RFID Warehouse Management Systems Cost?

RFID systems are more expensive than barcode systems. However, the initial cost can balance out over the long term through saved labor expenses and less lost inventory. The best decision depends on your industry and personal factors. Here’s a breakdown of RFID system costs:

- RFID equipment: RFID tags, readers, additional antennae and software can range in price depending on several factors. For example, the type of tags and readers you choose can impact cost. Software price will depend on its complexity, features and integrative capabilities with your existing systems.

- Integration and labor: The size of your warehouse and the complexity of the system can affect labor and installation costs. If you need to integrate the RFID system with existing software, that will be an additional expense.

- Maintenance and training: You’ll also need to factor in the cost of training staff to use the system. Maintenance and support fees will be ongoing expenses. However, once the system is correctly set up and running, these costs will be minimal.

To estimate the price of your RFID system, research the type of equipment that would be best for your products and warehouse. Next, you can reach out to several RFID companies to compare the costs of labor and system types. Because there are different kinds of RFID tags and equipment, there’s an RFID system that’s right for everyone.

Disadvantages of RFID Systems

It’s important to consider more than just the benefits of radio frequency identification. Here are several disadvantages to consider before investing in an RFID system for warehouse management:

- High costs: Compared to barcode systems, RFID systems are more expensive. The initial expense of equipment and installation fees can be a barrier for some businesses.

- Integration challenges: Integrating RFID systems may be challenging, depending on the software you already use. You might need a custom solution, which can mean more cost.

- Reader interference: RFID tags don’t always work well around metal or liquids. You may need specialty tags depending on your products or warehouse environment.

- Tag range: RFID tags only work within a certain range, depending on the type of tag you choose. It’s important to purchase the right kind of tag for your situation.

- Security risks: Because RFID stores data in the cloud, it’s a target for cybersecurity attacks. You need a strong cybersecurity defense if you plan to use an RFID system.

Before switching your tracking system, it’s important to consider RFID advantages and disadvantages. With careful research and planning, the advantages of an RFID system for warehouse management far outweigh the challenges. Only you can know whether upgrading your system will be worth the initial investment of time and financial resources.

How to Build an RFID Tracking System

To build an RFID warehouse inventory management system, your first step is research. You’ll need to consider the frequency, read range and cost of different RFID tag options. Make sure to consider your warehouse environment and the kind of merchandise you store and ship.

The right tags for your warehouse will make inventory management easier. They’ll respond well in your warehouse environment, stay intact during transportation and allow you to continuously track items through the supply chain. Once you’ve chosen the kind of tags you want, it’s time to consider reader equipment options.

You can choose from hand-held or fixed reader options. As their name suggests, hand-held readers can be carried by staff and used in any location throughout your warehouse. Fixed readers are built into the wall in one location. Make sure the reader you choose is compatible with your tags — not every reader works with every type of tag.

Once you’ve purchased the right equipment, you’ll need to find the right software for tracking and managing data from your system. Integrating this software with existing systems can make reporting, compliance and data analytics much easier across your organization.

After installation, you should test the system to ensure everything is working. You’ll need to train your staff on new procedures and equipment so they’re prepared to start using the new system. Continual monitoring and system maintenance can help ensure that everything goes smoothly during the transition.

RFID in the Supply Chain — Future Trends

RFID technology is here to stay. Here are several future trends to watch for as the landscape for tracking and warehouse management continues to evolve:

- Smaller tags: As RFID tag technology improves, smaller tags will make it even easier to give each product a unique and secure identifier.

- Sensor-embedded tags: New and improved sensors can alert you to changes in temperature and humidity in storage environments.

- Cloud integration: Newer RFID systems direct data to the cloud, where it can be stored and accessed from any location.

- Enhanced security: To protect against cyberattacks, RFID systems are starting to incorporate advanced encryption and authentication.

- AI analysis: As AI continues to develop, it will be used to analyze data, strengthen the supply chain and improve warehouse systems.

As RFID systems continue to improve, they should also become more affordable. This technology is already a significant upgrade from barcode scanning, and it’s exciting to consider how much farther RFID systems for inventory and warehouse management can go.

Discover Customized Global Logistics With EMO Trans

Looking for a logistics expert? Whether you’re tracking products with barcodes or RFID tags, we can help you navigate the world of logistics and find customized solutions that fit your business. We specialize in parts and accessories and work with many different industries. Our expansive logistics services include air services, ocean services, warehouse management services, and global transport.

When you partner with us, you can reduce shipping costs, improve efficiency and elevate cargo security. We’ve worked in the logistics industry since 1965 and have network offices in 120 countries. EMO Trans can help you with customs, compliance and tracking to take your business logistics to the next level.

Request a quote today and learn how we can support your tracking and logistics process!